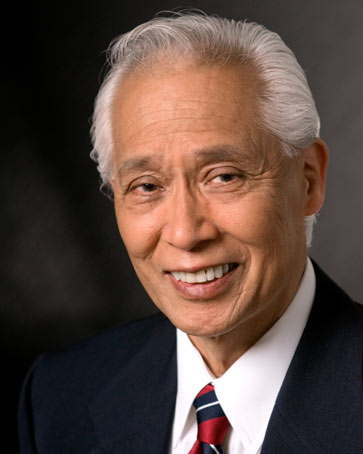

Freddie Tapuro

Campus Engineering and Operations

Nominated by Mark Easton, Power Plant Operating Engineer 2, Power Plant Shop 50

Awarded 2012

I nominate Freddie Tapuro for the University of Washington Distinguished Staff Award for his overall body of work and commitment to the University’s Power Plant and Facilities. In his service he has enhanced and preserved the mechanical element of the heart of the Facilities which is the energy, cooling and heating for the University of Washington Campus and Medical Center. Freddie’s assets and skills are utilized not because of job title but his own proactive desire to excel in his field above his job requirements. The University has benefited due to his unselfish work ethic and humility to the trade amongst the heat and noise of the work environment.

As his role with the Power Plant, Freddie is known in his unofficial title as the Lube Oil Mechanic. This means his has a chief responsibility of a check list numbered from item one to eight hundred and five. This check list is to insure the Preventive Maintenance and Lubrication of equipment throughout the Power Plant. These include but not solely limited to the Boilers, Chemical Pumps, Chill Water and Condensing Pumps, Chill Water Makeup Pumps, Cooling Tower Fans, Desuperheater Water Pumps, Cooling Water Pumps, Diesel Generator Fans and Radiator Fans, Feed Water Pumps, Fuel Oil Pumps, Gas Valves, Hot Well Pumps, Turbine Generator, and Steam Traps and Air Traps numbering items one through one-hundred sixty-six.

Moreover, this responsibility of these eight hundred and five items assigned to Freddie is done in fulfillment according to weekly, quarterly, bi-yearly and yearly checks. Hence, this responsibility helps enable the University Facilities to uphold and continue to provide the environment to enable discovery and excellence for the University as a whole.

One of the unique qualities of Freddie Tapuro is artistry in drawing. As a standard practice, with any new hire at the Power Plant, each is issued drawings of the Power Plant and its equipment drawn and colored by Freddie. The details are down to the floor grating. These drawings have been admired for his style and care of accuracy. The drawings are a treasure and document the Power Plant in an illustrated history.

Likewise, Freddie is a bit of a historian. His every personal workday for his position is documented and reduced to writing to have a work history for the year. First, in a quick draft and then carefully recorded and bond in an old or recycled folder. Along with this history will be pictures or line draft drawings for complicated maintenance issues or changes to equipment.

He also, makes note to give credit to those co-workers who completed work assignments attached to his position. This is also related to the labeling and dating of items done on the checklist and labels on the equipment itself to insure accuracy and work history.

In addition, Freddie is a welder. He is an excellent fabricator and uses this desired skill on projects that have included mixing tanks, steam piping, steam traps and amongst various projects and assignments from his supervisors. The fabrication along with the drawings and history is not haphazard but has style.

Freddie Tapuro seeks no recognition. He is very simple and does his job well and completely. He is humble and even cleans his own work station without complaint. He organizes his tools and equipment that is logical and functional. He accurately and precisely does the labeling of numerous five gallon oil buckets to fifty-five gallon barrels. He disposes properly oil rags and pads and cleans up spills without delay. It is the little things done right that make all the difference in the big things being done right.

Now in his seventies Freddie may not seek the lime light but his fellow co-workers seek the light to shine in honor upon him. I thank you for this opportunity to share about one the of the University of Washington’s special staff members and hope others may hear of Freddie Tapuro and his commitment to heart of Facilities Services.